Series

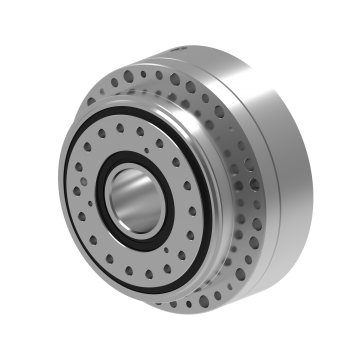

The H series represents TwinSpin high precision reduction gears with through-holes in the shafts, also known as the hollow-shaft version. Cables, tubes with compressed air, drive shafts and so on can be led through the hole in the shaft of the gear. The H series high precision reduction gears comprise an accurate reduction mechanism and high-capacity radial and axial cylindrical bearings. This design of the reduction gears allows the mounting of the load directly on the output flange or case without a need of additional bearings.

Advantages

- large input shaft diameter

- fully sealed

- zero backlash reduction gears

- high moment capacity

- excellent positioning accuracy and positioning repeatibility

- high torsional and tilting stiffness

- small dimensions and weight

- high reduction ratios

- high effeciency

- long lifetime

- easy assembly

TECHNICAL SPECIFICATIONS

H series features

|

Case |

|

|

Input flange connection |

|

|

Input shaft design |

|

|

Installation and operation characteristics |

Hollow-shaft reduction gears have a large hole in the input shaft allows cables, tubes or an additional shaft to pass through the reduction gear. Suitable for applications where the rotation of the input shaft is achieved by using a tooth belt or a similar arrangement.

|

H series ordering specifications

|

Name |

Size |

Ratio | Series version |

Shaft version | |

|---|---|---|---|---|---|

| H | S | ||||

|

TS

|

70 |

75 | H | 13 | • |

|

140 |

69, 115 | H | 36 | • | |

|

170 |

69, 125 | H | 42, 46 | • | |

|

200 |

63, 125 | H | 52, 56 | • | |

|

220 |

55, 125 | H | 62, 65 | • | |

Note: An example of an ordering code of a modified H series TwinSpin reduction gear with a motor flange: TS200 – 125 –H– H56 – M235 – P231. The markings M235 and P231 for a specific modification are defined by the manufacturer.

H series rating tables

|

Size |

Reduction ratio | Shaft inside diameter | Rated output torque |

Acceleration and braking torque |

Permissible torque at emergency stop |

Rated input speed | Cycle effective speed 5) | Max. allowable input speed10) | Tilting stiffness 1)6) | Torsional stiffness 1)7) | Max. no-load starting torque 9) |

Max. back driving torque 9) |

| i | d | TR [Nm] | Tmax [Nm] | Tem [Nm] | nR [rpm] | nef[rpm] | nmax [rpm] | Mt [Nm/arcmin] | kt [Nm/arcmin] | [Nm] | [Nm] | |

|

TS 70 |

75 | 13 | 50 | 100 | 250 | 2000 | 2500 | 5500 | 35 | 7,5 | 0,14 | 13 |

|

TS 140 |

69 | 36 | 200 | 500 | 1000 | 2000 | 1200 | 3500 | 340 | 55 | 1,6 | 110 |

| 115 | 4500 | 1,5 | 130 | |||||||||

| 1300 | ||||||||||||

|

TS 170 |

69 | 42 | 420 | 1050 | 2100 | 2000 | 1000 | 3200 | 1100 | 110 | 2,5 | 180 |

| 46 | 825 | 1650 | ||||||||||

| 125 | 42 | 1050 | 2100 | 1300 | 3700 | 2,2 | 240 | |||||

| 46 | 825 | 1650 | ||||||||||

|

TS 200 |

63 | 52 | 712 | 1780 | 3560 | 2000 | 1000 | 2700 | 2000 | 200 | 4 | 250 |

| 56 | 1100 | 2200 | ||||||||||

| 125 | 52 | 1780 | 3560 | 3700 | 3 | 300 | ||||||

| 56 | 1100 | 2200 | ||||||||||

|

TS 220 |

55 | 62 | 1100 | 2750 | 5500 | 2000 | 700 | 2400 | 2400 | 290 | 5 | 170 |

| 65 | 2000 | 4000 | ||||||||||

| 125 | 62 | 2750 | 5500 | 900 | 3400 | 3 | 350 | |||||

| 65 | 2000 | 4000 |

RIGHT TO CHANGE WITHOUT PRIOR NOTICE RESERVED

1/ Mean statistical value. For further information see chapter Torsional stiffness, Tilting stiffness.

2/ Load at output speed 15 rpm.

3/ Tilting moment Mc max value for Fa=0. If Fa ≠0, see chapter Tilting moment.

4/ Axial force Fa max value for Mc=0. If Mc≠0, see chapter Tilting moment.

5/ The effective speed can also be higher for lost motion bigger than 1 arcmin and for low values of oil viscosity. For lost motion lower than 0,6 arcmin please consult the effective speed with the manufacturer.

6/ The parameter depends on the version of the high precision reduction gear.

7/ The parameter depends on the version of the high precision reduction gear, ratio and lost motion.

8/ The values of the parameters are informative. The exact value depends on the specific version of the high precision reduction gear.

9/ Temperatures of the high precision reduction gear lower than 20°C will cause higher no-load starting or back driving torque.

10/ Depends on the duty cycle; a higher input speed may be still possible, please consult at manufacturer.

The ratios highlighted in bold are recommended by SPINEA as optimal versions in terms of price and delivery.

H series rating tables

|

Size |

Reduction ratio | Max. lost motion |

Average angular |

Hysteresis | Max. tilting moment 2)3) | Rated radial force 2) | Max. axial force 2)4) | Input inertia 8) | Weight 8) |

| i | LM [arcmin] | ATE [arcsec] | H [arcmin] | M c max [Nm] | F rR [kN] | F a max [kN] | l [10-4 kgm2] | m [kg] | |

|

TS 70 |

75 | <1,5 | ±30 | <1,5 | 142 | 2,8 | 4,1 | 0,061 | 1 |

|

TS 140 |

69 | <1,0 | ±17 | <1,0 | 1160 | 11,5 | 17 | 3,6 | 7,5 |

| 125 | |||||||||

|

TS 170 |

69 | <1,0 | ±17 | <1,0 | 2000 | 19,2 | 27,9 | 4,8 | 11,6 |

| 125 | |||||||||

|

TS 200 |

63 | <1,0 | ±15 | <1,0 | 3300 | 21,1 | 31,7 | 18,2 | 20 |

| 125 | |||||||||

|

TS 220 |

55 | <1,0 | ±15 | <1,0 | 4400 | 22,5 | 35,5 | 31 | 26 |

| 125 |

Important notes:

• Load values in the table are valid for the nominal life of L10 =6000 [Hrs].

• High precision reduction gears are preferred for intermittent cycles (S3-S8); the output speed in applications is inverted-variable. The continuous mode cycle (S1) is needed to be consulted with the manufacturer.

• Sealing versions are described in chapter Assembly instructions.

• Please consult the the maximum speed in a duty cycle with the manufacturer.

• The values in the table refer to the nominal operating temperature.

The ratios highlighted in bold are recommended by SPINEA as optimal versions in terms of price and delivery.

SK

SK DE

DE IT

IT RU

RU CN

CN