Robotics

We are the only European manufacturer of precise cycloidal reduction gears, directly involved in new development of robots of leading robot manufacturers.

The unique features of our reduction gears were developed mainly for the robotic industry. The dominant feature is the pure rolling friction inside the reduction gear and a single stage of reduction with a very high gear ratio, from 33 to 191. These two features improve the final properties of robot, such as repeatable precision, dynamic movements of arms, running costs, low vibration, and low noise.

The biggest success has been achieved in articulated robots and external peripheral robotic equipment. Our new G series reduction gear is our top product, which is able to meet the highest demands in the current development of robots and in the development of new robots in the future. We are ready to co-operate with every robotic company in new development of their products.

Related articles

KR 16 - an outcome of the most successful cooperation project in the history of company SPINEA®

SPINEA an excellent choice for outdoor robots

Lubricants in reduction gears TwinSpin® Oil versus grease

SPINEA® in vacuum and electronics applications

DriveSpin® Flat – yet it is flat

High precision reduction gears TwinSpin® in Cartesian robots

SPINEA® in spinal surgery

SPINEA Technologies in the area of innovations

Rotary actuator unit with Siemens motor integrated into the KUKA control system

Remote robotic camera systems for the film and broadcast industry

applications

6-axis robots

- High positioning precision

- Smooth run

- Low vibrations

- Wide range of torques (18 to 4500 Nm)

- Possibly covering all 6 axes

- Wide range of sizes and gear ratios

- Excellent wrist axis solution

Scara robots

- Excellent dynamic performance

- High torsional and tilting stiffness

- Smooth run

- Low vibrations

- Compact design

- Easy installation

- Reliability and long service life

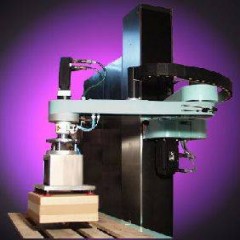

Gantry robots

- High torsional and tilting stiffness

- High power density

- Excellent dynamic performance

- Compact design

- Easy installation

- Reliability and long service life

Manipulators

- High power density

- High positioning precision

- High torsional and tilting stiffness

- Compact design

- Easy installation

- Reliability and long service life

OUR PRODUCTS

The notion TwinSpin® indicates the full integration of a high precision cycloidal reduction gear and a radial-axial bearing in a single unit.

DriveSpin® actuators represent the combination of the TwinSpin® reduction gear with an AC servomotor in a single compact unit.

Customer requirements often call for special solutions. Thanks to many years of experience in technical support and engineering, we realize highly professional solutions according to customer requirements.

Slewing drive and slewing bearing technology provide a large ratio in a single stage of gearing. For additional torque, we offer the option of adding an inline planetary gear to create a double reduction slewing drive

Harmonic gearing is zero to low backlash by design. It provides high transmission accuracy and can support a high ratio reduction in a single stage with low inertia.

We fully support worm with two input bearings allowing you to mount the gearbox in any position and increase your bearing life.

REFERENCES

¯¯¯¯¯¯¯¯¯¯¯¯¯¯

TESTIMONIALS

¯¯¯¯¯

Contact

Slavomír Sedlák

Specialist for Robotic Applications

+421 51 77 00 156

+421 918 400 942

slavomir.sedlak@spinea.com

SK

SK DE

DE IT

IT RU

RU CN

CN