Building industry: milli-meter Machine industry: micro-meter Electro-technical industry: nano-meter

Many different parameters are included in contemporary product catalogs. In the machine production area we are mostly interested in the characteristics as performance, loading capacity, lifetime, and cost; and also other secondary parameters typical for the machine production area.

Company SPINEA, s.r.o. is a producer of high precision reduction gears TwinSpin®.

Let´s talk about the characteristics of precision. Every industry branch associates precision with a different value – see the pictures up:

Precise machinery production most frequently uses the unit „micrometer“, which is the size corresponding to one-thousandth of a millimeter. Such preciseness cannot be seen or felt. Human senses are not capable of perceiving such value. Therefore we have to use high precision measuring devices in order to measure with micron-size precision.

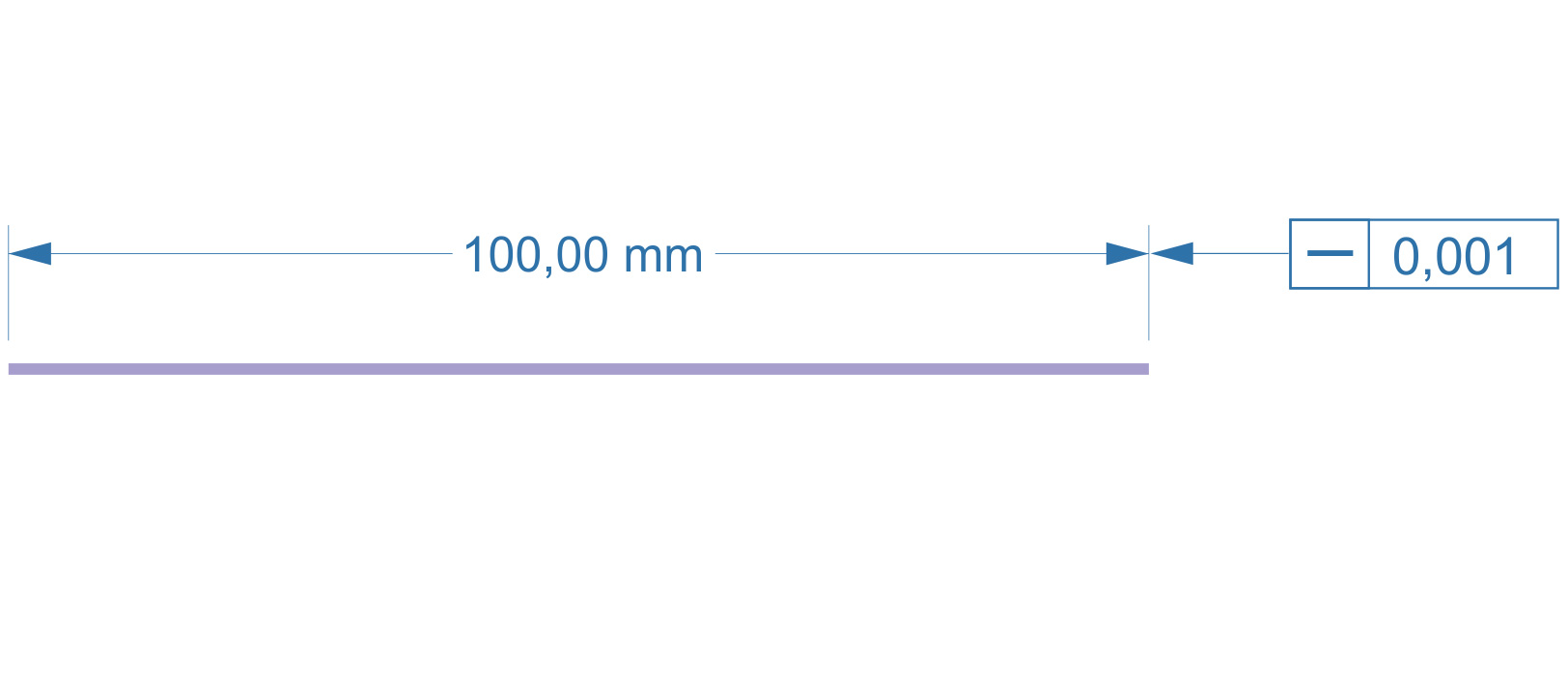

To be able to imagine such precision in human measures, we will explain it in the following text. Let´s take the parameter „straightness“.

Such a defined request towards machine designers means that no deviation from the shape should exceed 1/1000mm = 0,001mm within 100 mm length. It is hard to imagine such unevenness; therefore we will transform it into a visible measure.

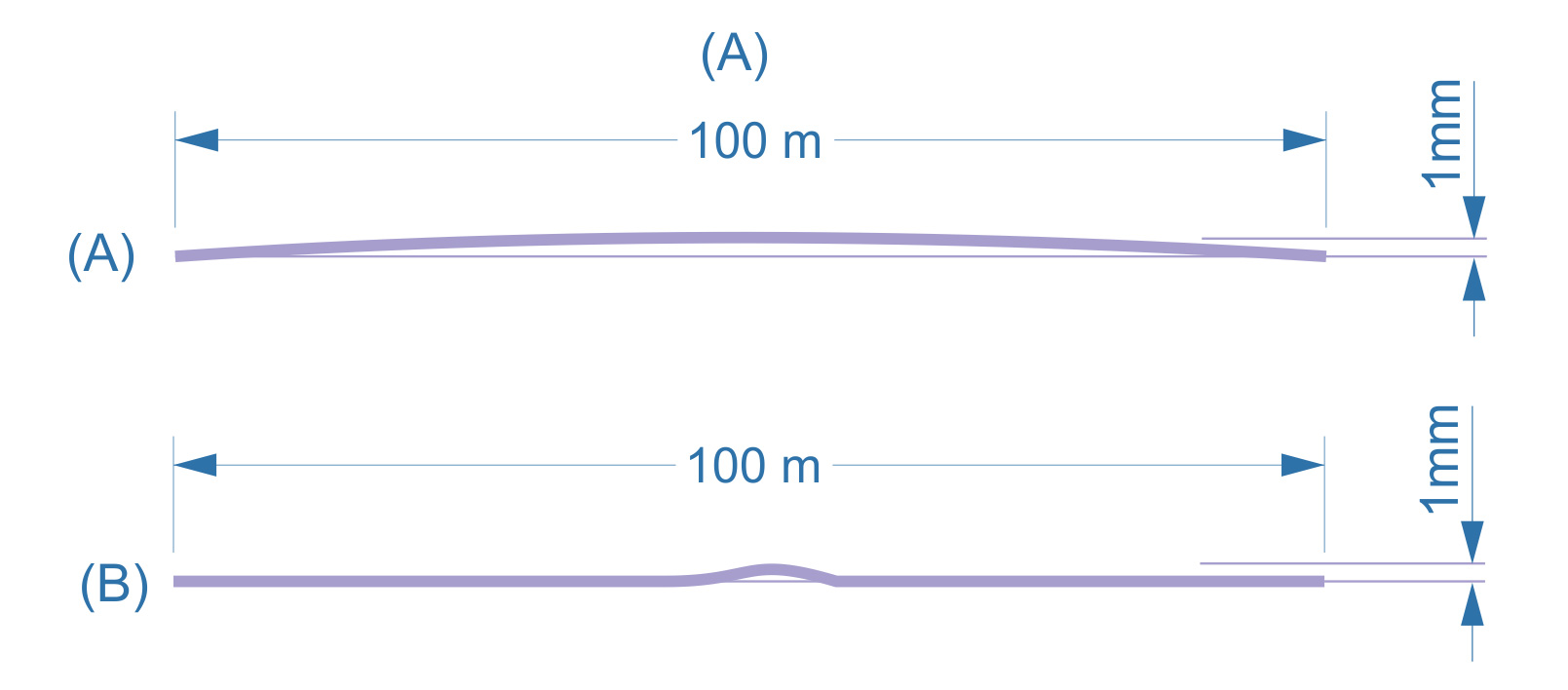

Many of us are vehicle drivers. To better understand the problem, imagine it on the road measure, keeping the proportion. We shall magnify it thousand times (x 1000).

Straightness: 0.001 mm x 1000= 1mm

Length: 100 mm x 1000 = 100,000 mm = 100 m

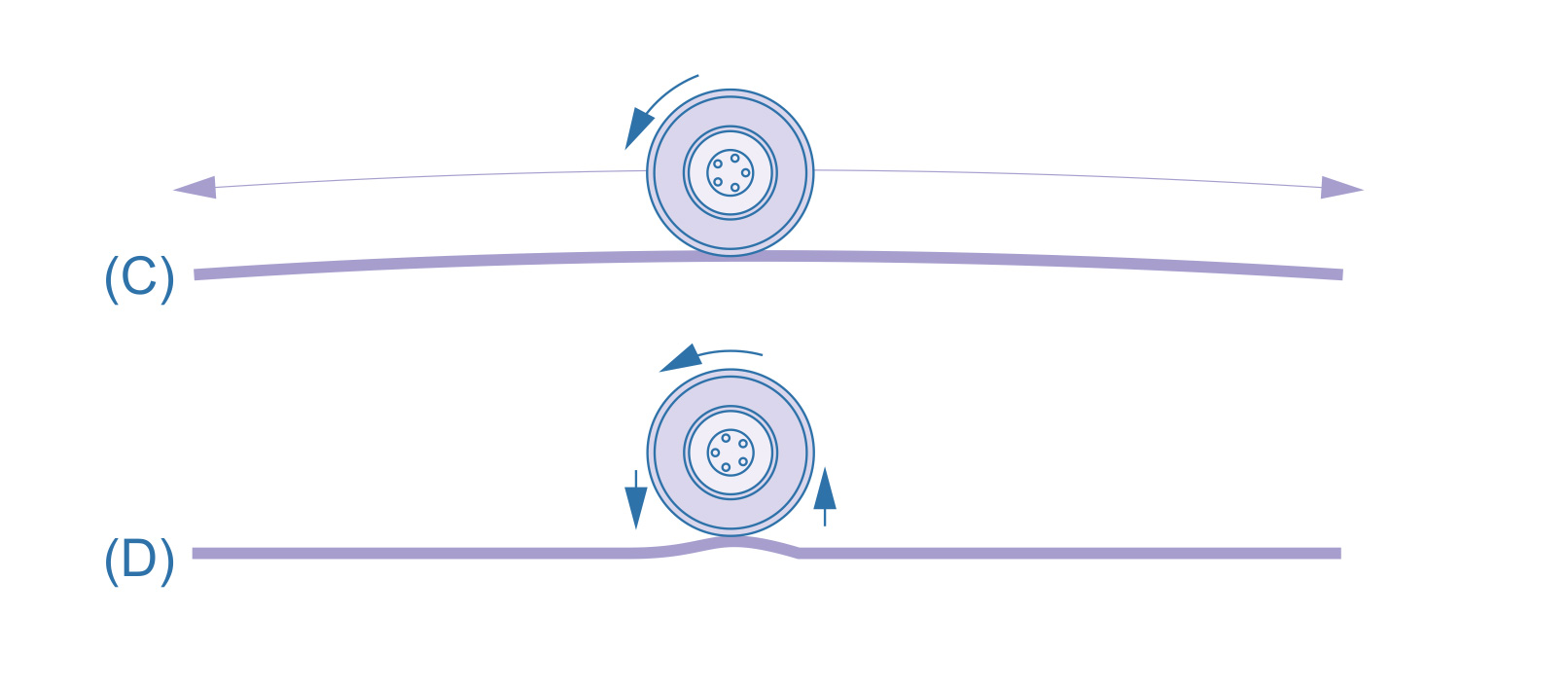

On a 100 m long road, maximum superelevation or protrusion could reach only 1 mm. A human eye is not capable of capturing such superelevation and the driver wouldn´t feel anything unusual in real situations; the vehicle would drive smoothly. However, the local protrusion can be captured by the eye, even. its response can be felt in the wheels. It is still a very small value.

This is the reason why we have to monitor the type of unevenness along with its superelevation during precision production. In the case of local, even small unevenness, it could cause vibrations or noise, similar to that perceived when driving a vehicle.

Production with micron-size precision is demanding in the terms of production and measuring technique. Company SPINEA, s.r.o. has managed the processes of very precise production as proved by top quality products that belong to the category of high precision technology.

SK

SK DE

DE IT

IT RU

RU CN

CN