SPINEA® is the manufacturer of TwinSpin® high-precision zero-backlash cycloidal gearbox that achieves very high positioning accuracy. Excepting precision, they have other useful features and are used in applications where small design envelopes and high overload capacity are required. One such application is automatic tool changer (ATC), which is part of every CNC machining center.

The basic parameters of the ATC are the number of tools in the tool magazine, the tool change time, and the size of the tool magazine. The main task of the ATC is fast and reliable tool change. During operation, there is a high dynamic movement of the magazine, where high loads are generated during acceleration and braking. TwinSpin® cycloidal gear is characterized by its high overload capacity, based on the robust design of the gearbox itself, and thus represents a reliable solution for the ATC drive unit.

In most cases, machining centers have limited space. It is therefore advantageous to use a gearbox to drive the ATC that has a high torque density i.e., a high ratio between the nominal torque and the gearbox's size or weight. Compared to other gearboxes, SPINEA® cycloidal gearboxes achieve a high value for this parameter is a single stage. This means that they are able to transmit high power within a small space and enable the implementation of a compact ATC design. In addition, TwinSpin® cycloidal gearboxes achieve high gear ratios of 100 or more, which allows the use of a smaller motor in the drive unit and thus further minimize its dimensions. The use of a smaller motor ultimately translates into lower energy consumption required for tool changes.

A major benefit for this application is the integrated high load capacity radial-axial output bearing directly in the reducer.

Basic types of ATC:

- Drum;

- Chain.

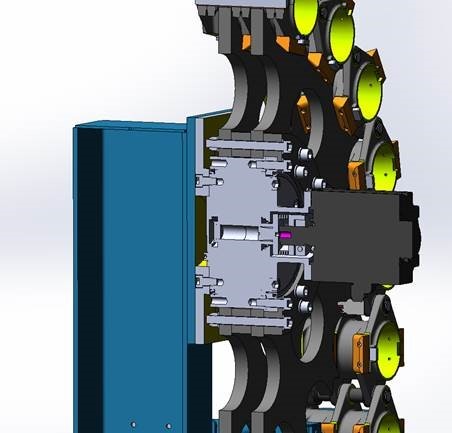

Depending on how the drum ATC is installed (horizontally or vertically), either axial or radial load and bending torque are applied to the gearbox. Chain ATCs (vertical) are high-capacity tool magazines where high radial forces are generated from gravity, chain tension, and also high torque overload during acceleration and braking. These forces are reliably captured by a radial-axial roller bearing at the gearbox output.

Another significant advantage of using TwinSpin® is the possibility of applying a gearbox the way in which the reducer case is rotated as the output, while the output flange is fixed to the ATC base. This allows the sprocket to be mounted directly on the reducer case, minimizing the axial dimension of the drive unit, increasing the compactness of the solution, and optimizing the forces acting on the reducer. This translates into a reduction in the magnitude of the tilting torque and, ultimately, in the increased lifetime of the drive unit. This method of application of the reducer is also shown in the pictures.

ATC manufacturers also appreciate the simplicity of the drive unit design when using the TwinSpin® cycloidal gearbox and the low costs of installation. TwinSpin® cycloidal gearboxes are filled with lubricant for their entire service life and require no maintenance or other operating costs.

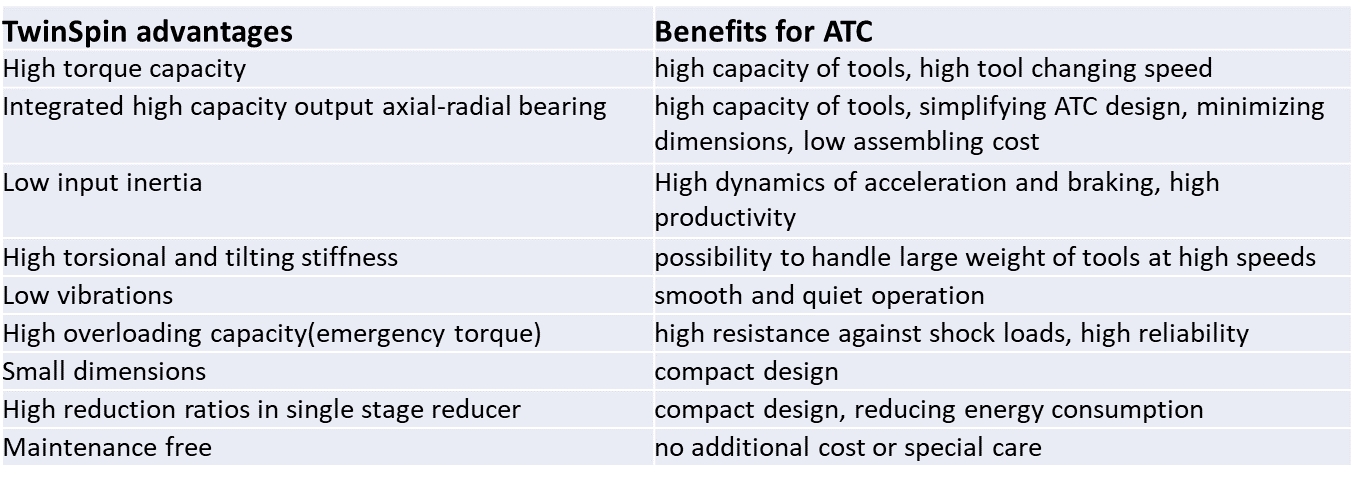

Summary of the advantages of TwinSpin® cycloidal gearboxes and their benefits for ATC:

The unique properties of the TwinSpin® cycloidal gearboxes are the reason why the designers of the world's major machine tool manufacturers apply TwinSpin® cycloidal gearboxes in the drive unit of the ATC.

If you are interested in the information provided in our article, we would be happy to answer any further questions you may have about the application of TwinSpin® cycloidal gearboxes in machine tools.

SK

SK DE

DE IT

IT RU

RU CN

CN