All gear equipment has functional limits when it comes to operating temperatures. Very often the spotlight is placed on high temperatures, less common is the focus placed on the low ones.

The majority of TwinSpin® gearbox applications run at ambient temperatures typical for industrial environments ranging from 10 up to 30 °C. But still, there are some applications that operate at lower temperatures, sometimes at extreme ones. A typical application area where lower temperatures are present is the food industry where in particular meat, fish, and dairy products require processing temperatures close to, or in some cases below 0 °C. Another type of low-temperature application is outdoor or high-altitude environments where temperatures can go as low as – 50 °C.

Oil or grease?

The choice of lubricant depends on the application type and the lowest temperature reached in the ambient.

The preferred choice when it comes to low-temperature applications is grease, usually special products designed for use in cold environments. In the food industry where the operating temperature is around zero oil is also used but with a lower ISO viscosity grade than standard grade 150.

Friction at low temperatures

The most desired property of a low-temperature lubricant is to allow proper lubrication and the lowest starting torque and no-load running torque possible. There is a big difference in friction torque magnitude in lubricants designed specifically for cold environments and standard ones, even if the technical specification states that it can withstand quite low sub-zero temperatures.

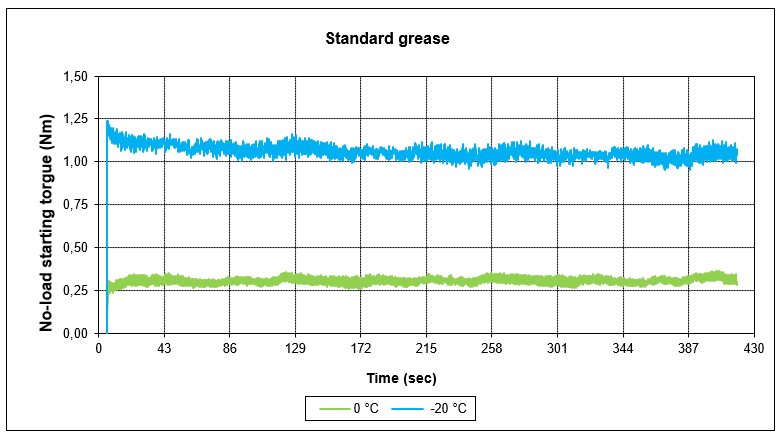

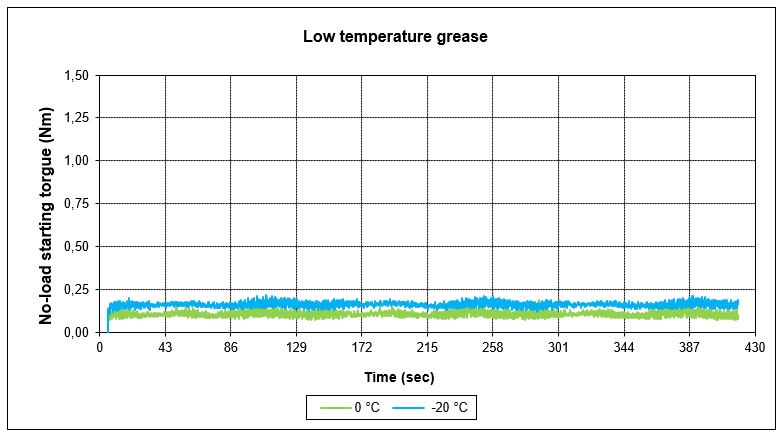

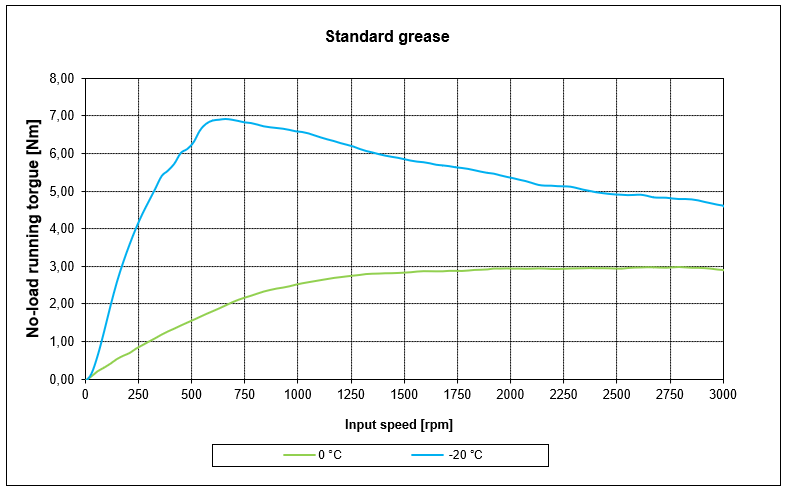

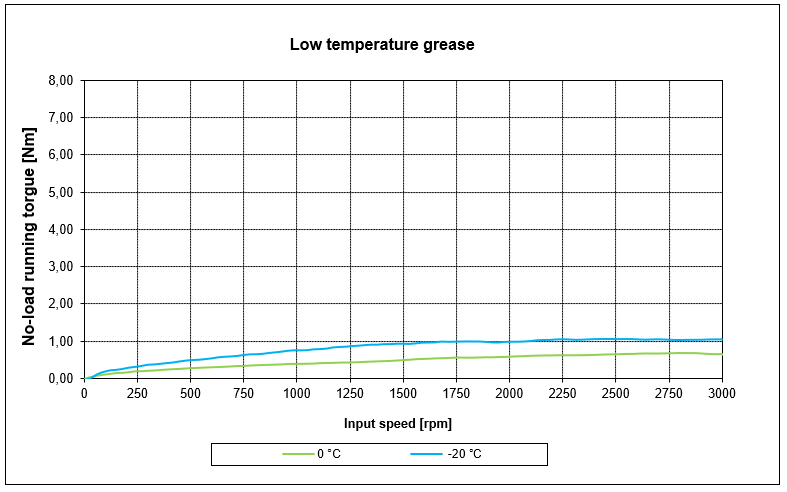

On the following charts, there are results presented of the test performed with a standard grease and with dedicated low-temperature grease.

The temperature limit of standard grease was -35 °C and low-temperature grease was - 60 °C.

Chart: 1

Chart: 2

Chart: 3

Chart: 4

As seen in the graphs above, the low temperature has an effect on static friction and also on viscous friction in the TwinSpin® gearbox. The difference in friction torque is significant even at zero Celsius where viscous friction of standard lubricant is more than triple the value of low-temperature lubricant.

Conclusion

It is important to always consider ambient temperature for each application. As you have seen on the above charts even temperatures around zero can influence friction torque in reducer and consequently the design of motion system. Depending on the application, designers should consider temperature influence and increased friction torque when selecting suitable servo drive, also in the cases when the temperature is low only for part of the working cycle until reducer is heated, or if the low temperature is acting only for a certain period of time, for example, if reducer working area is not heated during winter. Should you have further questions concerning the performance of TwinSpin® high precision gearboxes at low temperatures let contact us.

SK

SK DE

DE IT

IT RU

RU CN

CN